Outdoor digital signage touchpoints are usually integrated into totems or enclosures to protect the installation from the elements. In the mistaken belief that the enclosures provide sufficient protection as well as for cost reasons, many indoor components are installed. invidis and cooling filter manufacturer Gore explain how displays can withstand the harsh outdoor environments.

Choosing the right components for outdoor installations seems easy – high-brightness screens are widely available in all sizes, brightness levels and optional fully ingress-protected (IP). But here it usually stops. Additional non-customer facing components beyond the sunlight-readable display are often not fit for purpose. For various reasons, integrators and customers mostly choose indoor-use-only media players, 4G-modems, sensors, and other electronic components.

Surprisingly enough, there is a common belief in the industry that an IP-protected display and any type of outdoor enclosure are sufficient. Many integrators and customers lack extensive experience with outdoor digital signage, as high brightness screens have only become a digital signage commodity in recent years. But components within an outdoor enclosure are significantly more likely to fail than in indoor usage.

The biggest enemies for maintenance-free operations of digital signage are severe outdoor conditions and heat accumulation inside the enclosure. Heat derives from electronic components, the display, and especially from the sun. The recommended operating temperature for typical digital signage components is usually below 40°C. Each 10°C increase in operating temperature reduces the life of the electronics by 50% according to the Arrhenius equation. However, with the appropriate heat management solutions users can increase lifetime and reliability of electronic components.

Professional thermal management is necessary to ensure component longevity and prevent unplanned on-site maintenance. A reduction in capital expenditure (CAPEX) by selecting less expensive components instead of components that are approved for outdoor use seems feasible. But even an unplanned outage can drastically change the total cost of ownership (TCO) and brand value.

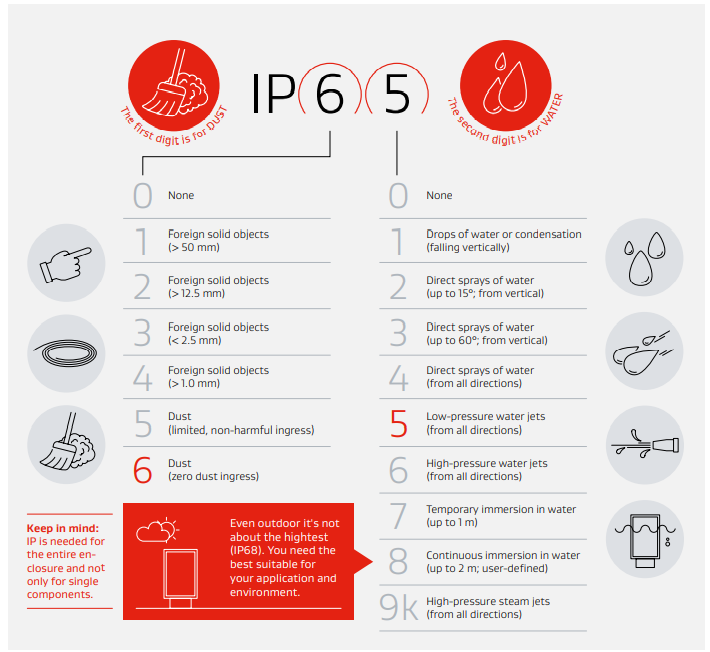

In order to get a grip on the heat inside the case, it is recommended to design sufficient cooling. Typical thermal management solutions include a fan and filter, also known as direct air cooling, a heat exchanger and air conditioning. The most economical and sustainable solution is often direct air cooling using a high performance filter and fan. This draws the ambient air into the housing. Unlike air conditioning, direct air cooling (DAC) and heat exchangers cannot cool below the ambient temperature. For extreme outdoor applications that require a protection class of IP66 or higher, fully encapsulated systems with a sealed heat exchanger are recommended. But CAPEX as well as operating expenditures (OPEX) are much higher than for DAC operated systems.

In addition to heat, there are hidden challenges for outdoor signage: corrosion from air pollution such as diesel exhaust, salt spray from coastal resorts or winter road treatments. Unprotected components can start to corrode and cause failures within a few months. So it is not only hot summers that pose a risk of serious malfunctions of digital signage components in outdoor use. For this reason, system protection and reliability should be an essential part of TCO management.

Get full access to all invidis yearbook articles – it’s free!

Download the industry bible for more analysis and market data. Secure your personal copy now – it’s free of charge.