Information screen, self-service kiosk or other interactive touch points – consumers expect touch interactivity of information digital signage displays if they are within reach. Touch is the preferred form of interactivity also in digital signage as we are used to interact with smartphones. But not every touch technology is suitable for this. We explain the differences.

The standard use-case for touch are kiosk terminals like ATMs or ticket vending machines in public transportation. The displays often react inaccurately and like to send users through unnecessarily nested menus. In addition, they can only be controlled with a single finger, which seems unfashionable nowadays. Frustration is the result.

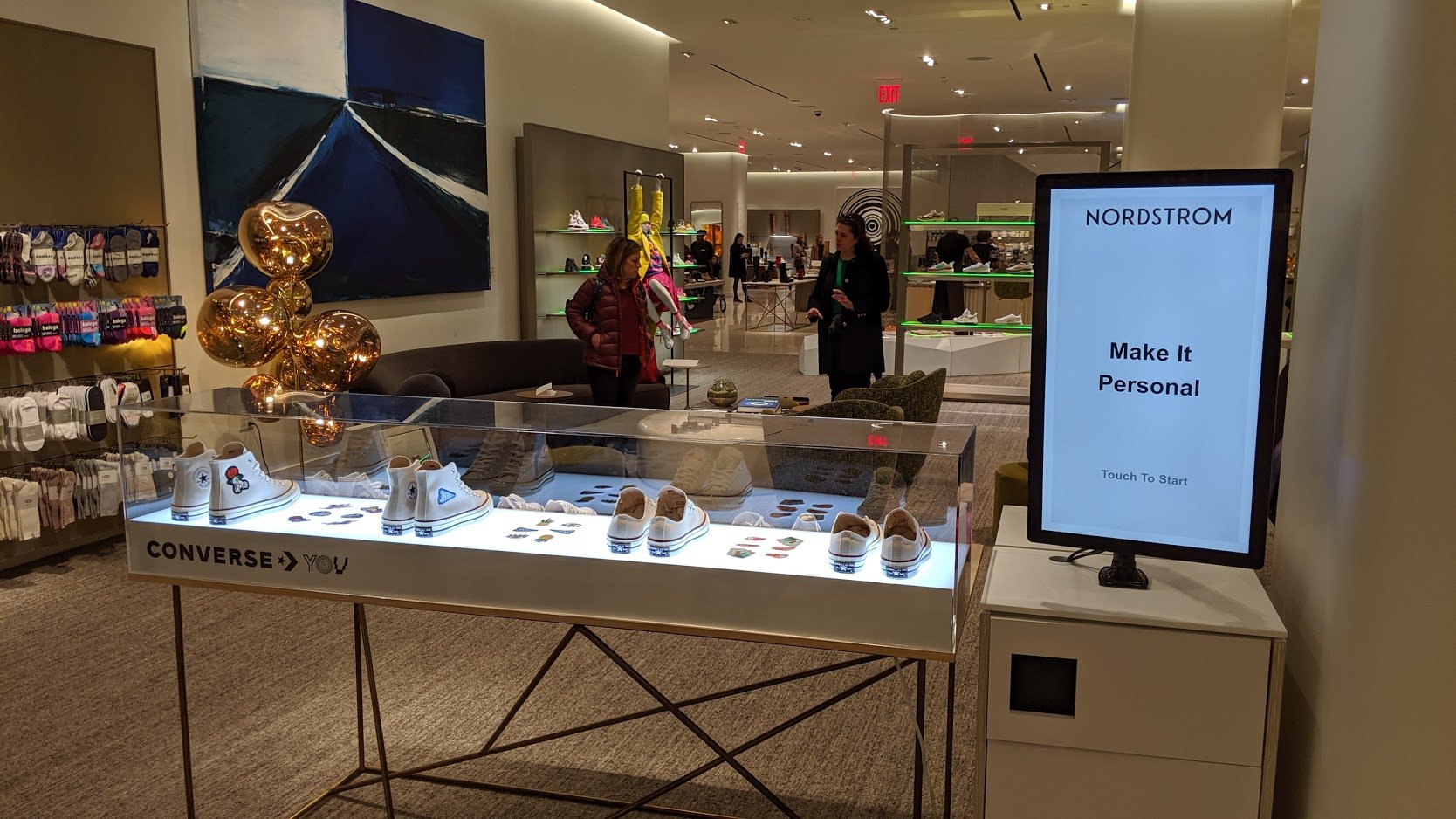

A better experience is offered by multi-touch displays, the demand for which is particularly high in the retail industry: whether as a checkout display, way-guiding or self-service terminals. At trade shows and exhibitions, multi-touch installations with up to 100 touch points are drawing the crowds for data driven presentations. However, the higher number of touch points the more expensive the solution becomes.

■ Touch-based interactivity and multimedia addressing have become standard in digital signage projects.

The market trend is clearly moving towards multi-touch application scenarios with more than two touch points and multi-user interaction. Several user can simultaneously operate a single screen.

The technologies:

Projective Capacitive Touch (PCAP)

PCAP touch technology has become the new standard for premium installations offering an impressive touch performance through pressureless touch while being sufficient robust for public use.

PCAP works with a sensor network of electrode pairs that are integrated into the glass surface as a transparent coating. These generate an outwardly acting electromagnetic field. The field between the electrodes is influenced by pressureless touching of the glass. By changing the electrical capacity, the touch position can be precisely determined. In contrast to common resistive touch monitors, PCAP also supports multi-touch functionality. The multi-touch function recognizes one-dimensional gestures such as wiping and scrolling or multi-finger control gestures such as zooming by rotating, spreading or closing the fingers.

Because PCAP displays are not reliant on pressure sensitivity, the surface of the screen does not need to be elastic. The front glass of such terminals is extremely robust with a hardness of 7H and guarantees high durability and scratch resistance. The touch functionality of projective capacitive displays remains unaffected even if the cover glass of the monitor is scratched or soiled.

PCAP touch displays can be operated with suitable gloves or pens with magnetic tip, which makes them also interesting for industrial applications, e.g. for use in manufacturing and control rooms.

Infrared Touch

Touch displays with infrared are mostly used as interactive large format solutions for common meeting rooms and classrooms. Infrared touchscreens use transmitters and receivers that create an invisible grid of infrared beams across the screen. If the infrared beams are interrupted by a finger or pen, the exact position can be determined. The technology is cost-effective even for large format sizes and can be operated with a finger or pen at up to 20 simultaneous touch points. Dirt or long-term dust accumulation can affect the technology as the touch-frame is positioned on top of the display.

Resistive Touch

Touch terminals that are used 24/7 in public spaces or in industrial environments must be particularly resistant. Touch displays in outdoor areas need to be very robust and protected against vandalism, the elements of nature and extreme temperature fluctuations. For such applications, where robustness and reliability are more important than crisp picture quality, displays with resistive touch technology should be used, which are also cost-effective.

Resistive touchscreens do not react to a light touch, but to pressure sensitivity. They consist of two electrically conductive layers, a glass or plastic pane on which a flexible polyester layer lies, separated from each other by spacers, so-called space dots. The two inner surfaces are coated with a transparent semiconductor. The actual display is located below the two layers. If pressure is now applied, the two layers are connected in places at this point. Since the layers form a voltage divider on which the electrical resistance is measured, the position of the pressure point can be determined exactly by the electronics.

However, resistive touch technology generally does not allow multi-touch, only single-touch interaction and the widespread use of gestures is not really supported. Resistive touchscreens can be operated not only with the finger (even with gloves), but also with various media, e.g. any type of pen.

Resistive touch monitors are often used in outdoor and semi-outdoor kiosk terminals, and for automation solutions and the control of production plants and in logistics.

Optical Touch

Optical touch technology is based on the interruption of light beams. Instead of a pressure-sensitive layer on top the screen surface, optical touchscreens use a number of infrared light-emitting diodes (LEDs) and light-sensitive sensors or cameras within the frame of the display, forming a narrow grid of infrared light beams just above the screen surface. If a finger or object interrupts this grid of rays at any point, the touchscreen controller can use the optical information from the cameras to calculate the touch point and determine the X and Y coordinates of the touch position.

A major advantage of optical touchscreens is that they can be operated not only with bare or gloved fingers, but also easily with a stylus or other objects. Optical touch is a touch technology in which the glass surface of the display is not part of the sensor technology. This makes it possible to work with particularly robust glass surfaces that offer high protection against mechanical or chemical damage. Nevertheless, complete transparency and thus the best image quality can be guaranteed because there is no coating of the glass surface by an overlay or substrate layer.

Optical touchscreens are therefore used especially where extreme demands are placed on the touchscreen surface, such as in public institutions and offices, in schools and education, industry or medical technology. The same applies, of course, to kiosk systems at the PoS/PoI with large-area displays, such as those found at trade fairs, airports or railway stations.

Surface Acoustic Wave Touch (SAW)

Surface Acoustic Wave touchscreens use special transducers that are mounted on the edge of the panel and lay an invisible grid of ultrasonic waves on the surface. On the opposite sides of the transducers are sensors that receive the ultrasound.

SAW touchscreens can be operated with the finger or with a special soft pen. They can only register one touch at a time. When the glass screen is touched, the sound is partially absorbed. The receivers register this change, from which the controller calculates the XY coordinates of the touch point.

SAW touchscreen

s can be flat or curved and can be combined with LCD displays. Since their surface is made of glass, they are not susceptible to scratches or general wear and tear. They can therefore be used in public information systems, ticket machines or other POI systems. SAW touchscreens are available in all possible sizes up to 50 inch screen diagonal.

Get full access to all invidis yearbook articles – it’s free!

Download the industry bible for more analysis and market data. Secure your personal copy now – it’s free of charge.